IPS Nuclear Service

We are certified to provide services and repairs for nuclear safety- and non-safety-related motors and other rotating equipment in compliance with all federal regulations and nuclear standards.

Other commercial shops are available for non-safety-related repair, depending on customer preference.

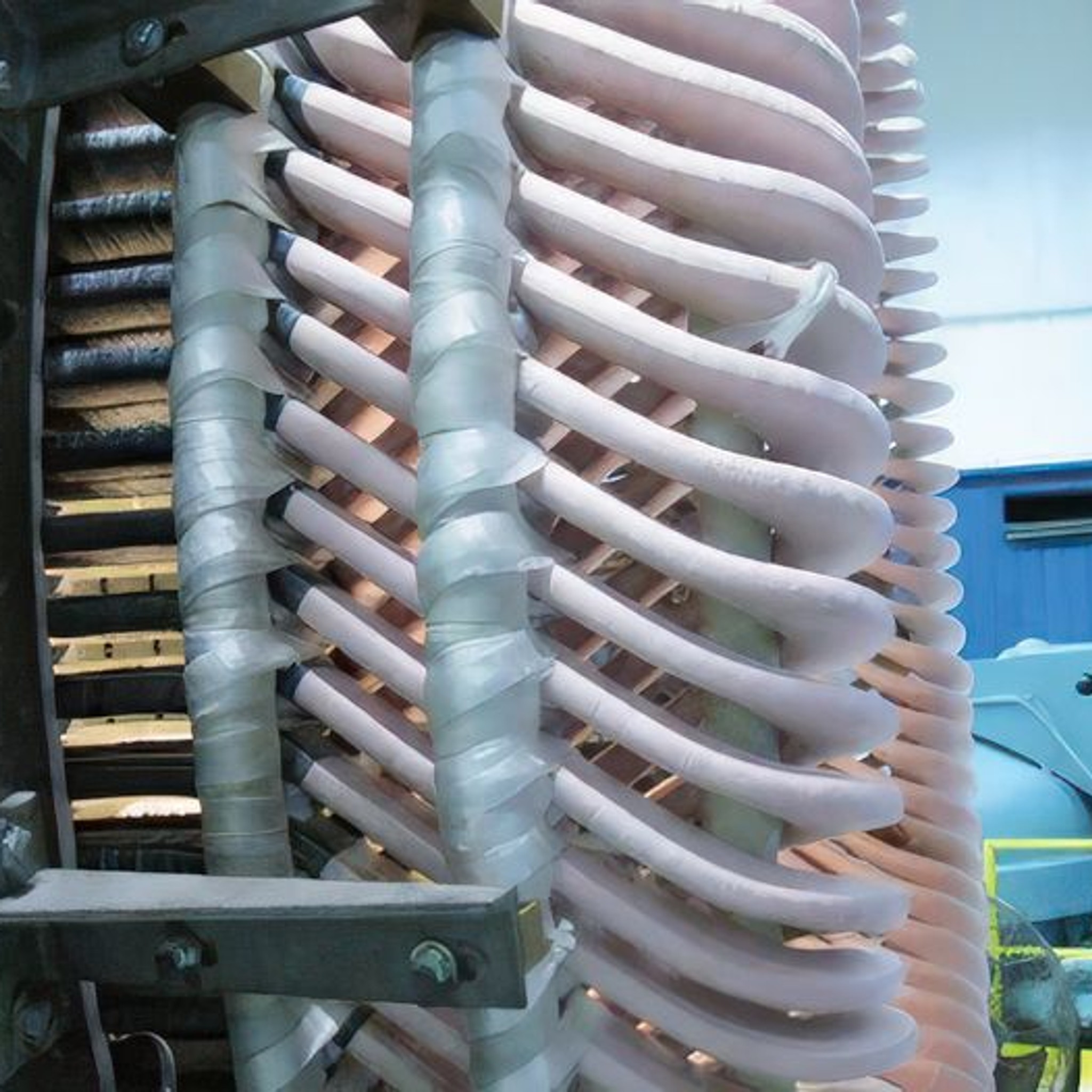

IPS low-voltage rewinds with the Reliance NUC-9 insulation system

Most U.S. nuclear plants were originally supplied with non-safety-related, safety-related, and environmentally qualified low-voltage motors using the insulation system specified in the Reliance NUC-9 and NUC-22 qualification reports.

These legacy Reliance Electric® insulation systems are designated “Type RH” and “Type RN” qualified insulation systems. We maintain the same materials and processes for providing like-for-like, OEM equivalent rewinds for motors certified to the original qualification report. No design change is required for any application with an existing NUC-9 insulation system.

A strong culture of quality

IPS delivers consistent quality to support nuclear plants. We have decades of experience with meeting the individual specifications of all major nuclear utilities.

The IPS Nuclear Quality Assurance Manual provides the framework to ensure that the work of our engineers and technicians meets or exceeds customer specifications. We welcome compliance audits by qualified, independent third parties concerning IPS capabilities to meet or exceed customer and regulatory performance requirements.

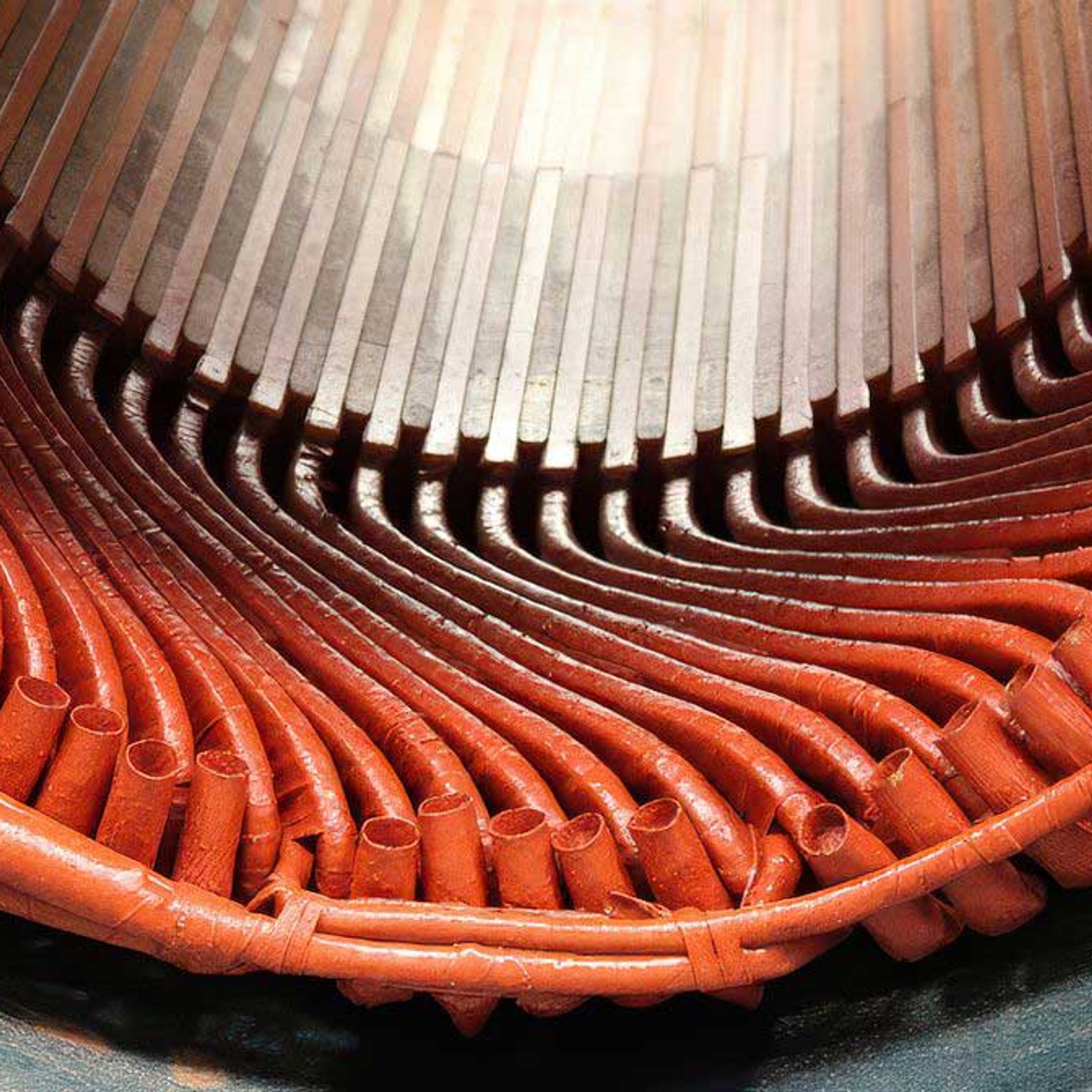

The industry’s highest capacity for nuclear motor & generator repair

IPS has repaired virtually every OEM motor in the nuclear industry, including General Electric, Westinghouse, Siemens-Allis, and Baldor-Reliance. We offer the industry’s largest VPI tank, to support the rewind of any nuclear motor.

We also have extensive experience rigging and transporting extra-large motors and generators via super-carriers.

Engineering for nuclear applications

We design engineers specialize in both new and legacy equipment engineering, design, and performance. We engineer for nuclear applications, including large motors and pumps, to provide purpose-built drop-in replacements, as well as like-for-like, OEM-equivalent replacements wherever possible.

Many of our engineers have over 30 years of experience with rotating electric machinery. This includes OEM design, engineering, and repair experience with companies such as GE, Reliance, EM, Siemens, Toshiba, Ideal Electric, Westinghouse, TECO, and others.

The IPS Reliance NUC-9 insulation system

NUC-9 is engineered and qualified to exceed the requirements of 10CFR50.49 and NRC Reg. Guide 1.89.

Reliance Electric and IPS engineers completed extensive testing to achieve this level of performance and reliability.

Radiological decontamination

IPS partners with multiple decontamination facilities, depending on location and availability.

This helps us minimize cost and lead times for contaminated motor repair.

Commercial-grade dedication

IPS maintains a robust commercial-grade dedication program. We procure commercial-grade components and dedicate them for safety-related use, as required via Failure Modes and Effects Analysis (FMEA) and customer requirements.

This program is modeled after EPRI TR 3002002982. IPS has expanded its 10CFR50 Appendix B quality assurance program to include commercial grade dedication of new motors for the nuclear industry.

Diversification to support the drive train

IPS has added extensive experience in repairing and reconditioning centrifugal pumps, including modifications and upgrades — including safety-related applications.

IPS also offers additional rotating equipment capabilities for non-safety-related applications. We repair pumps, blowers, compressors, and fans.

Technical field services and support for nuclear plants

IPS provides experienced technical field services for nuclear plant motors and rotating equipment. IPS PowerServe adds to our capabilities with NETA-certified technicians.

We also provide condition monitoring and authorized warranty repair, plus replacement parts.

Emergency & outage support decontamination

IPS partners with multiple decontamination facilities (depending on location), leveraging scale and experience, to deploy field service teams and resources across North America. We’re on-site fast when equipment goes down with the trucks, cranes, portable generators, and critical spares you need.

IPS single-source capabilities streamline plant emergency response. You can manage one trained and certified service provider on-site instead of coordinating the work of multiple vendors.

Motor storage in accordance with EPRI 1009698 and ANSI N45.2.2 Level B

IPS meets all packaging, shipping, storage, and handling (PSS&H) requirements for equipment used in nuclear power plants. Our professional asset management and documented maintenance reduce unplanned downtime and capital investments.

We maintain a proven storage and asset management system with strategic warehousing across the U.S. IPS has 650,000+ square feet of temperature- and humidity-controlled storage space, free of resonant vibrations.

Nuclear motors and replacement/spare parts

In addition to new motor dedication, IPS offers like-for-like replacements via new motor manufacturing or surplus motor remanufacturing for select end-use applications. Our internal distribution services let us leverage lower costs that we forward to the customer.

We offer multiple repair or replace options when you need new parts and equipment.