IPS offers coast-to-coast in-shop remanufacturing for large national accounts.

We test, service, repair, and remanufacture with networked resources, including:

- Complete electrical testing

- Industrial motor repair from fractional HP through 80,000+ HP/15,000

- Dedicated small motor departments

- Complete pump, fan, blower, and compressor repair and rebuilds

- Mechanical repairs and machining

- Power distribution equipment repair, reconditioning, and remanufacturing

Complete electrical testing

IPS tests to document “as received” and “as shipped” performance, with multiple tests to validate recommendations.

IPS electrical tests include:

- Run testing through 15,000 VAC/1,000 VDC

- No-load testing up to 37,500 HP @ 13.8 kV

- Full-load testing through 4,500 HP @ 13.8 kV

- IEEE 43 Insulation Resistance — Megger®

- IEEE 43 Polarization index Ratio

- IEEE 95 Hi-Pot AC/DC to 100 kV

- IEEE 1043 Voltage Endurance to 13.8 kV

- IEEE 1434 Partial Discharge

- IEEE 1776-2008 Water Immersion to 13.8 kV

Large & extra-large AC & DC motor and generator repair

IPS tests, rewinds, reverse engineers, and remanufactures large and extra-large electric motors and generators. We also redesign and rewind for uprating horsepower or efficiency.

IPS offers the industry’s leading premium VPI rewinds. Our engineers and design team handle frequency conversions, speed change rewinds, conversion to inverter duty, or voltage changes.

VPI tanks at every service center, including the industry’s largest (14’ x 17’)

145-ton lift capacity

Dynamic balancing up to 80,000 lbs.

Dedicated small electric motor repair

IPS maintains dedicated small electric motor repair cells across our North American network. These small motor repair specialists focus on low-voltage units up to 690 VAC.

We offer cost-competitive service with warranties and short lead times for a variety of small electric motors.

- NEMA motors

- IEC motors

- Arbor motors

- Gear motors

- Servo motors

- Spindle motors

- Low-voltage DC motors

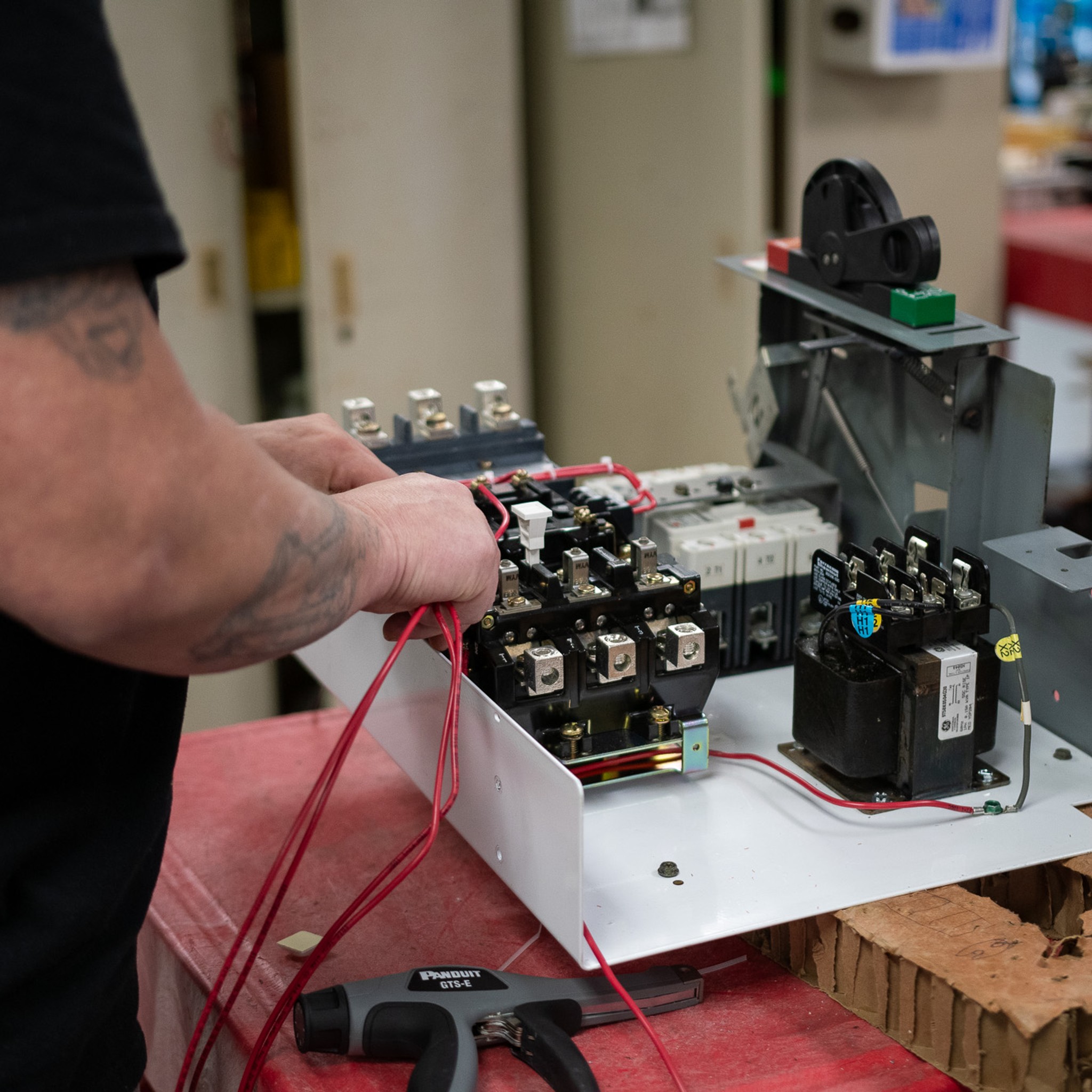

In-shop test, repair, and reconditioning services

Our in-shop technicians specialize in surplus electrical equipment remanufacturing, rebuilding, and reconditioning. IPS inspects, tests, disassembles, and restores circuit breakers, switchgear, and related parts.

We test each completed product to OEM, PEARL, and InterNational Electrical Testing Association (NETA) quality standards. Final inspection includes a 34-point visual inspection by the repair technician and QC supervisor.